Productive

Quality

Sustainable

Collaborate

Products for pig dehairing

With which parts do you ensure the best pig depilation? So how do you always get the machine parts delivered on time and how can you blindly rely on the quality? The most important task for slaughterhouses is that the slaughter line runs without interruptions. That is why we produce and supply just-in-time made-to-measure parts for pig depilation.

NIJHUIS SLAUGHTERING TECHNIQUE

Nijhuis Group produces and sells various overhaul parts for slaughter machines. We are specialists in pig dehairing and make various types of high quality parts for pig dehairing, so that they will last a long time. We do this with our years of Nijhuis Slaughtering Technology knowledge.

Large and small slaughterhouses all over the world belong to our clientele. They choose our products because of the exclusive quality, customization, service and long life of the parts. Our customers choose for productivity and durability.

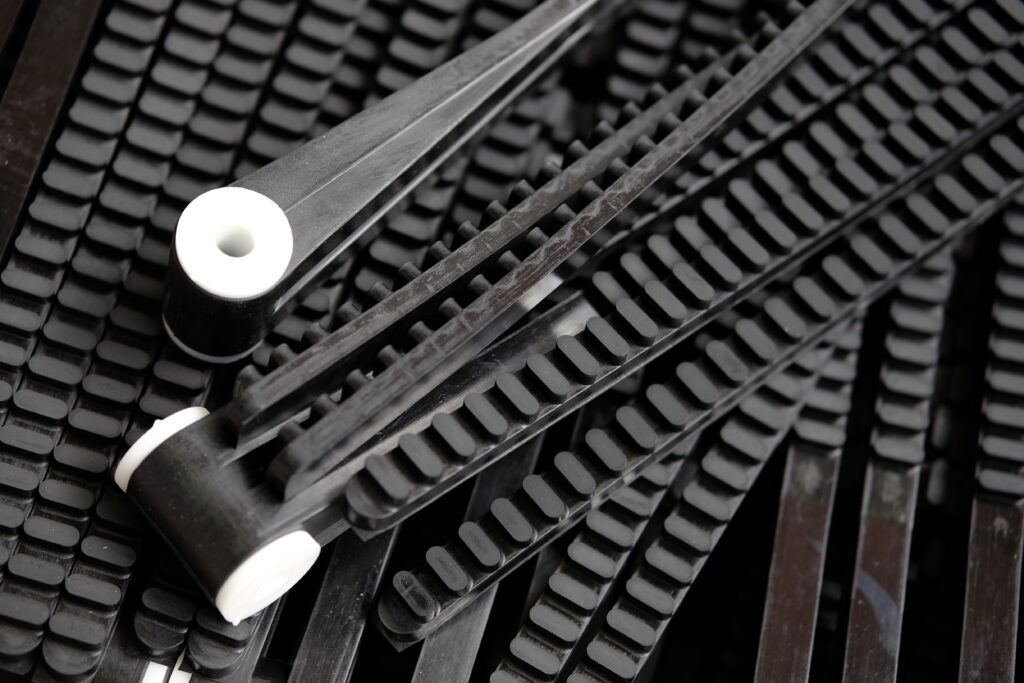

DEHAIRING SCRAPERS, SCRAPER BLOCKS OR HOG PADDLES

Our Nijhuis Group rubber pig dehairing scrapers, also known as hog paddles or scraper blocks, are wear-resistant and resistant to animal fat, urine and disinfectants. The scrapers are made of extra strong galvanized steel. As a result, they remain sharp and do their work for a long time.

WE MAKE THE BEST SCRAPERS IN THE WORLD.WE HAVE MADE ABOUT 1 MILLION PIECES WITHOUT COMPLAINTS!

The scrapers have a specific construction and consist entirely of nylon layers inlaid in natural rubber. Due to the specific density of the natural rubber, the product remains flexible and strong in structure. As a result, the hair removal scrapers have a much longer lifespan than others. In combination with our special fastening set, you have an optimal cost-saving revision set in your hands.

Robotisering

With a rich history in slaughtering techniques and a strong focus on innovation and technology, including the automation of our own production processes, we are your reliable partner for solutions that enhance efficiency, quality, and sustainability in the food processing industry.

PIG DEHAIRING WHIPS

Our rubber pig dehairing whips then ensure the optimal pre- and post-treatment of the pigs. These whips go into the whip or cleaning machine.

The whips are one- or two-legged and made of white or black natural rubber. They are extra flexible and strong for a long lifespan.

(ROLLER)HOOKS FOR PIG DEHAIRING

We also produce various types of (coil) hooks and spreaders, made of aluminium, stainless steel and/or steel. These ensure optimal transport of the pigs in the dehairing process. For example:

- Complete leg chains for the automatic uncoupling in Tarzan or Banss machines;

- Euro hooks;

- Roller hooks;

- Spreaders.

CLEAR ORIGIN OF RAW MATERIALS

Our quality is also monitored with great care. Raw materials are supplied with certificates concerning food safety and REACH. In addition, our suppliers are all located locally. In this way, our sustainable quality products contribute to the prevention of disruptions in the slaughter process. The total slaughter costs in the pig depilation chain are also reduced.

CUSTOMER RETENTION THROUGH QUALITY, SPECIAL DESIGNS AND SPEED OF DELIVERY

We also keep the customers we have. They choose our products first and foremost to set up the base in the hair removal process properly. After all, slaughterhouses are slaughtering more and more pigs on the same slaughter line. As a result, the parts in the dehairing machine have to endure more and more.

Optimal depilation of the pigs is essential in the slaughter process. If a pig is not properly cleaned, the slaughter line is shut down. The quality and durability of the spare parts is therefore becoming increasingly important.

Are you also looking for the best pig dehairing products? Call us or read more about the products we can offer!

Order our products online

Would you like to request a quote or order our slaughter technology products online? Then visit our webshop now!